|

Wihersaari, Margareta

VTT Processes, Koivurannantie 1, P.O.Box 1603, FI–40101 JYVÄSKYLÄ, Finland

VTT Publications 564, May 2005, 93 p. + app. 71 p.

[in English]

ISBN 951–38–6445–6

(soft back ed.)

ISBN 951–38–6446–4 (PDF edition)

Project: SIHTI Programme, PUUENERGIA Programme

Commissioned by National Technology Agency of Finland, Tekes; the Academy of Finland

Keywords: greenhouse gases, emissions, energy supply systems, biofuels, bioenergy, biomass production, wood fuels, forest residues,

municipal wastes, renewable energy sources

Abstract

Greenhouse gas emission assessments of energy supply systems have traditionally included the CO2 emissions produced as the fuel is burned. A lot of models and calculations for evaluating greenhouse gas emission savings

by using bioenergy have been introduced. The approaches often cover a major part or sometimes even the whole energy system.

The biofuel production process itself is one piece that is normally covered very briefly or considered insignificant. Unfortunately,

this means that the significance of some affecting factors might not have been estimated. The object of the thesis was to

study the greenhouse gas balances in connection with the harvesting and production of biofuels and, based on this, evaluate

in what situations there is a need to re-evaluate the potentials of greenhouse gas emission savings when using bioenergy for

substituting fossil fuels.

Different methodologies were used in the separate evaluations: the philosophy and methodology of industrial ecology was used

to analyse the sustainability and material flows of the Finnish forest industry. A simple calculation model was developed

for analysing the energy consumption and greenhouse gas emissions for biomass production chains, upgrading of biofuels and

production of solid recovered fuels. Emission risks from long-time storage of biofuel and biodegradable material were evaluated

as well as changes in forest soil carbon due to harvesting of forest residues. The examination of the biofuel production chains

showed that in a favourable situation as much as 97–98% of greenhouse gas emissions for a fossil fuel could be avoided by

substituting it with a biofuel. On the other hand the investigation also pointed out that e.g. increasing fuel storage and

upgrading activities for biofuels are likely to decrease this percentage remarkably. The main conclusion of the thesis was

that the neutrality of greenhouse gas emissions when producing bioenergy should be re-evaluated. The author further suggest

that tools and stimulants for keeping the greenhouse gas emission levels in fuel production chains as low as possible should

be developed.

Contents

Abstract

Preface

List of original publications

Units and abbreviations

1. Introduction

1.1 Global warming and energy related greenhouse gas emissions

1.2 Renewable energy – a technical measure to reduce the energy related greenhouse gas emissions?

1.3 The contents and objectives of the thesis

2. Methods and materials

3. Aspects on greenhouse gas emissions related to using biofuels for substituting fossil fuels

3.1 Forest fuels as a part of the utilisation of forest biomass

3.2 Energy efficieny and greenhouse gas emissions of biofuel production chains

3.2.1 Forest residue

3.2.2 By products

3.2.3 Biofuel cultivation

3.2.4 Upgrading biofuels

3.2.5 Aspects on substituting fossil fuels with a biofuel

3.3 Potential greenhouse gas emissions from storage of biofuels

3.4 Utilisation of forest residues and the effect on the carbon pool in forest soil

3.5 Aspects on considering municipal waste as a biofuel

3.6 Biomass or municipal waste disposal considered as a base scenario

3.7 Uncertainties of the calculations

4. General discussion

4.1 Discussion of the results

4.2 Further discussion and recommendations

5. Summary

References

Appendices

mega watt hour

nitrous oxide

Forestry

Bark

Order of priority for the results

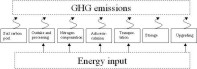

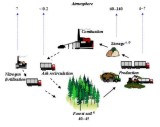

Figures and Tables Figure 1. Different ways of generating biomass suitable for biofuel production.  Figure 2. Some studied elements of the forest residue fuel production chains.  Figure 3. The expression “energy balance” used in this thesis refers to the external energy input in proportion to the biofuel

output.

Table 1. Parameter values used in model calculations (Table 1 in Paper V).

|

Parameter

|

Value

|

Parameter

|

Value

|

|

anwl

|

1.0 a-1

|

ksol

|

0.5 a-1

|

|

afwl

|

0.5 a-1

|

Kcel

|

0.3 a-1

|

|

acwl

|

0.05 a-1

|

klig

|

0.15 a-1

|

|

cnwlsol

|

0.27

|

Khum1

|

0.013 a-1

|

|

cnwlcel

|

0.51

|

Khum2

|

0.0012 a-1

|

|

cfwlsol

|

0.03

|

psol

|

0.15

|

|

cfwlcel

|

0.65

|

Pcel

|

0.15

|

|

ccwlsol

|

0.03

|

Plig

|

0.18

|

|

ccwlcel

|

0.69

|

Phum1

|

0.18

|

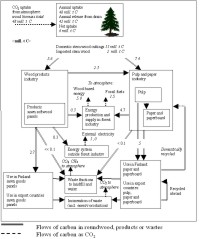

Figure 4. Flow chart of the soil carbon model. The boxes represent carbon compartments, the arrows carbon fluxes and the text

by the arrows parameters controlling the fluxes. The values used for the parameters are shown in Table 1 (Fig. 1 in Paper

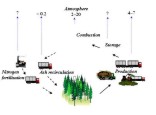

V).  Figure 5. Various ways of producing wood derived fuels in Finland.  Figure 6. Flows of wooden materials in the Finnish forest industry in 1997 (Fig. 5, Paper I).  Figure 7. The carbon flows in Finnish forest industry in 1997 (Fig. 8 in Paper I).  Figure 9. Flows of base cation nutrients in a forest ecosystem (Fig. 2 in Paper I).  Figure 10. Fuels used and production of electricity, process heat and space heat in the Finnish forest industry in 1997 (Fig.

7 in Paper I).

Table 2. Calculated energy input and GHG emissions for five wood chips production chains in Finland (Table 1, Paper III, modified). The outtake of forest residue is considered to be equal in all chains (100 loose m3 ha-1).

|

Input values and calculated results

|

Unit

|

Production chain

|

|

|

|

Terrain

chipping

|

Roadside

chipping

|

Terminal

chipping

|

Chipping at end use

Facility, transported:

|

|

|

|

|

|

|

Loose

|

baled

|

|

Losses along the production chain

|

w-%

|

0

|

10

|

5

|

10

|

5

|

|

To combustion:

fuel chips

moisture content

as energy

|

loose m3

w-%

MWh per haforest land

|

100

55

83

|

90

45

79

|

95

40

85

|

90

40

81

|

95

55

79

|

|

Energy need along the production chain:

production (diesel)

long distance transportation (diesel)

chipping (electricity)a)

|

l per MWhchip

l per MWhchip

kWhel per MWhchip

|

1.6

0.6

0

|

1.9

0.5

0

|

2.3

0.4

0

|

0.8

0.8

3.3

|

1.5

0.7

3.6

|

|

Energy input/output

|

%

|

2.1

|

2.3

|

2.6

|

1.9

|

2.6

|

|

Emissions from energy use during production chain

of which from electricitya

|

kg CO2eq per kWhchip

|

6.0

|

6.5

|

7.4

|

4.2

0.04

|

6.1

0.04

|

Figure 11. The magnitude of GHG emissions from a full fuel chip production and combustion chain (Fig. 2 in Paper III, modified).

Table 3. Evaluation of energy input and GHG emissions for agricultural by- products. The presented values were calculated

for straw and corn in Hungary (Wihersaari 2003, modified).

|

|

Energy input/output

%

|

GHG emissions

kg CO2eq per MWhbiofuel

|

|

Collection

|

1

|

2.7

|

|

Transportation, distance 20 km

|

0.4

|

1.0

|

|

Fuel preparationa (chopping)

|

0-0.4

|

0–1.0

|

|

Nutrient compensation

|

0-3

|

0–15

|

|

Total

|

1.4–4.8

|

3.7–19.7

|

Table 4. Evaluation of energy input and GHG emissions for energy forestry (poplar) in Hungary (Wihersaari 2003).

|

|

Energy input/output

%

|

GHG emissions

kg CO2eq MWhbio-1

|

|

Establishment, maintenance

|

0.3

|

0.7

|

|

Harvesting, transport on field

|

2.0

|

5.4

|

|

Chipping

|

1.4

|

4.0

|

|

Nutrient compensation

|

2.1

|

5.6

|

|

Transportation, distance 50 km

|

0.4

|

1.0

|

|

Total

|

6.2

|

16.7

|

Table 5. Evaluation of energy input and greenhouse gas emission evaluations for producing upgraded biofuels in Hungary (Wihersaari 2003, modified).

|

Biofuel source

|

Upgraded biofuel

|

Energy input per energy output

%

|

GHG emissions

kg CO2eq MWhbiofuel-1

|

|

Forestry

|

syngas

pellet

pyrolysis oil

|

3–5

~ 35

~ 20

|

8–16

~ 75

40–60

|

|

By-products of wood processing

|

pellet

|

5–33

|

13–69

|

|

By products of agricultural production

|

syngas

|

2–6

|

6–25

|

|

Energy forestry

|

syngas

pellet

|

8

~ 39

|

21

~ 86

|

Table 6. Emission profile of fossil fuels used in Finland (kg per MWhfuel) (Wihersaari 2003).

|

|

CO2 from burning

|

CO2eq from burninga

|

CO2eq domestic

|

CO2eq abroad

|

CO2eq

total

|

Production

burning-1

|

|

Coal

|

333.7

|

337.3

|

2.4

|

34.5

|

374

|

11%

|

|

Natural gas

|

200.9

|

204.5

|

15.4

|

43.4

|

263

|

29%

|

|

Fuel oil

|

275.8

|

279.4

|

16.5

|

16.5

|

312

|

12%

|

Table 7. Emission profile of the Hungarian fossil fuels (kg CO2eq MWhfuel-1 (Wihersaari 2003).

|

|

Burninga

|

Production chain

|

|

Productionaverage

Burning-1

|

|

|

|

Domestic

|

Averageb

|

Averagedomc

|

|

|

Coal

|

337.3d

|

98.4

|

92.2

|

88.8

|

27%

|

|

Natural gas

|

204.5

|

11.2

|

46.9

|

3.5

|

23%

|

|

Fuel oil

|

279.4

|

31

|

32.4

|

20.9

|

12%

|

Figure 12. The magnitude of GHG emission savings in Hungary when replacing coal with bio-chip, oil with bio-oil and gas with bio-gas. For 'min dom' and 'max dom,' only the domestic

emissions are calculated for, for 'min total' and 'max total,' also the emissions abroad are noticed. The unit is kg CO2eq MWhfuel-1 (Wihersaari 2003).

Table 8. Wood derived fuels used as energy in Finland 2002 (Statistics Finland 2003).

|

Wood derived fuel

|

Energy use in 2002, TWh

|

|

Black liquor

|

40.4

|

|

Industrial wood residues

|

|

|

Bark

|

15.3

|

|

Sawdust

|

4.5

|

|

Chip from wood residue

|

1.6

|

|

Other wood fuels

|

0.8

|

|

Forest chip

|

3.3

|

|

Other small combustion of wood

|

13.0

|

|

Total

|

78.9

|

Table 9. An evaluation of annually utilised volumes of bark, sawdust and fuel chip in Finland, their typical moisture and

energy content and appearing length of storage time.

|

Wood fuel

|

Typical moisture content

|

Typical energy content

|

Estimated volume used as fuel 2002

|

Rough estimation of storage periods

|

|

|

w-%

|

MWh per loose m3

|

mill. loose m3

|

months

|

|

Bark

|

40-65

|

0.6

|

25

|

0-12

|

|

Sawdust

|

45-60

|

0.6

|

8

|

0-12

|

|

Chip

|

45-55

|

0.8

|

5

|

0-6

|

Figure 13. Simplified temperature behaviour assumed for two types of decomposing forest fuels (Fig. 2 in Paper IV).  Figure 14. A principal estimation of cumulative greenhouse gas emissions for storage of two kinds of fuel chip with different

decomposing behaviour. The assumed temperature level inside the storage heap is the same as shown in Fig. 13 (Fig. 3 in Paper

IV, modified).  Figure 15. Studied elements of the SRF production chain.

Table 10. An overall estimate of the uncertainty of the estimates made in the thesis.

|

Error source

|

Order of priority for the results

|

Uncertainty

|

|

|

|

Energy balance

|

GHG emission

|

|

Production of base biofuels

|

+

|

L

|

L

|

|

Upgrading biofuels

|

+++

|

L/M

|

L/M

|

|

SRF production

|

++

|

L/M

|

L/M

|

|

Ash recirculation

|

o

|

L

|

L

|

|

Nitrogen fertilisation

|

+

|

L

|

L

|

|

Forest soil carbon pool

|

+++

|

o

|

H

|

|

Storage

|

++++

|

H

|

H

|

|

Landfilling

|

++++

|

o

|

M

|

Figure 16. The magnitude of GHG emissions (kg CO2eq MWh-1) from different parts of a fuel chip production chain ( a)The calculated magnitude of these emissions have to be considered more uncertain than the other.b) Evaluated for a six month storage of chip). (Fig. 2 in Paper III, modified).

References

Advisory Board for Waste Management. 1992. Yhdyskuntien jätehuollon kehittämisohjelma 2000 (Development programme on municipal waste management 2000). Ympäristöministeriön

ympäristöosaston selvitys 106/1992. Helsinki: Ministry of Environment. 54 p.

Alakangas, E., Kanervirta, M.-L. and Kallio, M. 1987. Kotimaisten polttoaineiden ominaisuudet. Käsikirja (Properties of biomass and peat fuels. Handbook). Espoo: VTT Research Notes 762. 125 p. ISBN 951-38-2969-3

Alakangas, E. 2000. Suomessa käytettävien polttoaineiden ominaisuuksia (Properties of fuels in Finland). Espoo: VTT Research Notes 2045. 172 p. + app. 17 p. ISBN 951-38-5699-2; 951-38-5740-9. http://www.vtt.fi/inf/pdf/tiedotteet/2000/T2045.pdf

Antikainen, R., Haapanen, R. and Rekolainen, S. 2004. Flows of nitrogen and phosporous in Finland – the forest industry and use of wood fuels. Journal of Cleaner Production, 12,

pp. 919–934.

Arnäs, P. O., Blinge, M., Bäckström, S., Furnander, Å. and Hovelius, K. 1997. Livcykelanalys av drivmedel (Life cycle and fuel). Göteborg, Sverige: Chalmers University of Technology, Department of Transportation and Logistics, Report no 95.

Beck-Friis, B. 2001. Emissions of ammonia, nitrous oxide and methane during composting of organic household waste. Uppsala:

Swedish University of Agricultural Science. Doctoral thesis. Agraria 266.

Beck-Friis, B., Pell, M., Sonesson, U., Jönsson, H. and Kirchmann, H. 2000. Formation and emission of N2O and CH4 from compost heaps of organic household waste. Environmental Monitoring and Assessment, 62, pp. 317–331.

Brännström-Nordberg, B.-M. and Dethlefsen, U. 1998. Livscykelinventering för bioenergi- och fossileldade kraftvärmeverk (Life

cycle inventories for bioenergy and fossil-fuel fired co-generation plants). Stockholm: Vattenfall Utveckling Ab, Projekt

Bioenergi, Rapport nr 1997/6.

BTG 2002. Methane and Nitrous Oxide Emissions from Biomass Waste Stockpiles – Final Report, August 2002. Prepared for World

Bank – PCFplus Research. The Netherlands: BTG biomass technology group BV.

Börjesson, P. 1996a. Energy analysis of biomass production and transportation. Biomass and Bioenergy, Vol. 11, No. 4, pp.

305–318.

Börjesson, P. 1996b. Emissions of CO2 from biomass production and transportation in agriculture and forestry. Energy Convers. Mgmt, Vol. 37, Nos 6–8, pp. 1235–1240.

Börjesson, P. 2000. Economic valuation of the environmental impact of logging residue recovery and nutrient compensation.

Biomass and Bioenergy, 19, pp. 137–152.

Cvengros, J. and Povanzanec, F. 1996. Production and treatment of rapeseed oil methyl esters as alternative fuels for diesel

engines. Bioresource Technology, 55, pp. 145–152.

European Commission. 1997. Energy for the future – renewable sources of energy. White paper for a Community Strategy and Action

Plan. COM(97)599, Brussels.

Finér, L., Mannerkoski, H., Piiranen, S. and Starr, M. 2003. Carbon and nitrogen pools in old-growth, Norway spruce mixed forest in eastern Finland and changes associated with clear-cutting. Forest Ecology and Management, 174, pp. 51–63.

Finnish Statistical Yearbook of Forestry 1999. Finnish Forest Research Institute, 1999:6.

Finnish Statistical Yearbook of Forestry 2003. Finnish Forest Research Institute, 2003:45.

Forsberg, G. 2000. Biomass energy transport. Analysis of bioenergy transport chains using life cycle inventory method. Biomass and Bioenergy, 19, pp. 17–30.

Franzluebbers, A. J. 2005. Soil organic carbon sequestration and agricultural greenhouse gas emissions in the southeastern

USA. Soil & Tillage Research. Article in press.

Gustavsson, L., Börjesson, P., Johansson, B. and Svenningsson, P. 1995. Reducing CO2 emissions by substituting biomass for fossil fuels. Energy, Vol. 20, No. 11, pp. 1097–1113.

Gustavsson, L. 1997. Energy efficiency and competitiveness of biomass based energy systems. Energy, Vol. 22, No. 10, pp. 959–967.

Gustavsson, L. and Karlsson, Å. 2002. A system perspective on the heating of detached houses. Energy policy, Vol. 30, pp.

553–574.

Hakkila P. (ed.) 1992. Metsäenergia (Forest Energy). Helsinki: Finnish Forest Research Institute. Metsäntutkimuslaitoksen tiedonantoja 422.

Hakkila, P. 2004. Developing technology for large-scale production of forest chips. Wood Energy Tecnology Programme 1999-2003. Final report. Technology Programme Report 6/2004. Helsinki.

Harju, T. 2001. Puuenergiapolton materiaalivirrat (Material streams of wood fuel combustion). Osahankkeen loppuraportti Tekesin Puuenergian teknologia-ohjelmassa. VTT Kemiantekniikka.

Hovelius, K. and Hansson, P.-A. 1999. Energy- and exergy analysis of rape seed oil methyl ester (RME) production under Swedish conditions. Biomass and Bioenergy,

17, pp. 279-290.

Impola, R. 1998. Puupolttoaineiden laatuohje (Quality assurance manual for solid wood fuels in Finland). Stockholm: Vattenfall Utveckling Ab, FINBIO Julkaisuja/Publications 6.

IPCC 1995. IPCC Guidlines for National Greenhouse Gas Inventories. Volumes 1–3, Greenhouse Gas Inventory – IPCC/OECD National

GHG Inventory Programme, Paris, France.

IPCC 1996a. IPCC second assessment synthesis of scientific-technical information relevant to interpreting Article 2 of the

UN Framework Convention of Climate Change.

IPCC 1996b. Climate Change 1995 – economic and social dimensions of climate change, contribution of Working Group III to the

Second Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press. 448 p.

IPCC 1997. Greenhouse Gas Inventory Reference Manual. Revised 1996 IPCC Guidlines for National Greenhouse Gas Inventories.

Volumes 1-3.

IPCC 2001a. Climate Change 2001. The Scientific basis. Contribution of Working Group I to the Third Assessment Report of the

Intergovernmental Panel on Climate Change. Cambridge University Press.

IPCC 2001b. Climate Change 2001. Mitigation. Contribution of Working Group III to the Third Assessment Report of the Intergovernmental

Panel on Climate Change. Cambridge University Press.

Jungmeier, G., Resch, G. and Spitzer, J. 1998. Environmental burdens over the entire life cycle of a biomass plant. Biomass and Bioenergy, Vol. 15, No. 4/5, pp. 311-323.

Kaltschmitt, M., Reinhardt, G. A. and Stelzer, T. 1997. Life cycle analysis of biofuels under different environmental aspects. Biomass and Bioenergy, Vol. 12, No. 2, pp. 121-34.

Kyoto Protocol 1997. The United Nations Framework Convention on Climate Change.

Kofman, P. D. and Spinelli, R. 1997a. An evaluation of harvesting machinery for short rotation coppice willow in Denmark. Elsamprojekt. Fredericia, Denmark.

Kofman, P. D. and Spinelli, R. 1997b. Storage and handling of willow from short rotation coppice. Elsamprojek. Fredericia, Denmark.

Korpilahti, A. 1998. Finnish forest energy systems and CO2 consequences. Biomass and Bioenergy, Vol. 15, No. 4/5, pp. 293–297.

Kuoppamäki, R. 2001. Mekaanisen metsäteollisuuden sivutuotteiden poltto-teknisten ominaisuuksien parantaminen. Osaraportti 3. Kuoren varastointi (Part 3. Inventory of bark). VTT Energia, ENE2/T0019/2001.

Kuoppamäki, R., Impola, R., Fagernäs, L. and Ajanko, S. 2003. Puupolttoaineiden muutokset varastoinnissa ja kuivauksessa.

Osaraportti 1 (Changes in wood fuel properties because of storage and drying. Part 1). VTT Processes, Project Report PRO5/T6090/02.

Kuusisto, E., Kauppi, L. and Heikinheimo, P. (eds.). 1996. Ilmastonmuutos ja Suomi. (Climate Change and Finland). Helsinki University Press. 265 p. ISBN 951-570-296-8.

Lehtilä, A., Savolainen, I. and Tuhkanen, S. 1997. Indicators of CO2 Emissions and Energy Efficiency. Comparison of Finland with other countries. Espoo: VTT Publications 328. 80 p. + app. 31 p. ISBN 951-38-5204-0; 951-38-5205-9. http://www.vtt.fi/inf/pdf/publications/1997/p328.pdf

Lilliesköld M. and Nilsson, J. (eds.). 1997. Kol i marken – konsekvenser av markanvändning i skogs- och jordbruk (Carbon in

soil – consequences of land use in forestry and agriculture). Stockholm: National Swedish Environmental Protection Board,

Report 4782.

Liski, J., Ilvesniemi, H., Mäkelä, A. and Starr, M. 1998. Model analysis of the effects of soil age, fires and harvesting on the carbon storage of boreal forest soils. European Journal of Soil Science, 49, pp. 407-416.

Lundborg, A. 1998. A sustainable forest fuel system in Sweden. Biomass and Bioenergy, Vol. 15, Nos 4/5, pp. 399–406.

Malinen, H. 1997. Forecasting Demand and CO2-emissions from Energy Production in the Forest Industry. Doctoral Thesis. Lappeenranta: Research papers 65.

Marosvölgyi, B., Halupa, L. and Wesztergom, I. 1999. Poplars as biological energy sources in Hungary. Biomass and Bioenergy, 16, pp. 245–247.

Marttila, M. and Leinonen, A. 1999. Seospolttoaineiden varastoinnin kehittäminen. Loppuraportti 1997–1999. (Development of storage of mixture fuel) Project Report ENE32/T0047/99.

Metsätilastotiedote 2002. Puupolttoaineen käyttö energiatuotannossa vuonna 2001 (The use of wood fuels in energy production

2001). Metsäntutkimuslaitos: Metsätilastotiedote 620. 5 p.

Mälkki, H., Hongisto, M., Turkulainen, T., Kuisma, J. and Loikkanen, T. 1999. Vihreän energian kriteerit ja elinkaariarviointi

energiatuotteiden ympäristö-kilpailukyvyn arvioinnissa (Green energy criteria and life cycle assessment in assessing environmental

competitiveness of energy products). Espoo: VTT Tiedotteita 1974. 117 p. ISBN 951-38-5466-3; 951-38-5467-1. http://www.vtt.fi/inf/pdf/tiedotteet/1999/T1974.pdf

Mälkki, H. and Virtanen, Y. 2001. Hakkuu- ja sahatähteiden energiakäytön elinkaariarviointi (LCA of energy use of logging

and saw mill residues). Tekes, Puuenergian teknologiaohjelma 2001.

NIR 2003. Greenhouse Gas Emissions in Finland 1990-2002. National Inventory Report to European Commission. Common Reporting Formats (CRF) 1990-2002. Ministry of Environment, Finland.

Nordlund, G. 1998. Ilman epäpuhtaudet. In: Mälkönen, E. (ed.). Ympäristömuutos ja metsien kunto. Jyväskylä: Metsäntutkimuslaitoksen tiedonantoja, Vol. 691. Pp. 46–53.

Nurmi, J. 1999. The storage of logging residue for fuel. Biomass and Bioenergy, Vol. 17, pp. 41–47.

Olsson, B., Staaf, H., Lundkvist, H., Bengtsson, J. and Rosén, K. 1996. Carbon and nitrogen in coniferous forest soils after

clear-felling and harvest of different intensity. Forest Ecology and Management, 82, pp. 19-32.

Palosuo, T. and Wihersaari, M. 2000. Puuenergia ja kasvihuonekaasut. Osa 2: Hakkuutähteiden energiakäytön vaikutus metsien maaperän hiilitaseeseen (Energy use

of forest residues – impact on soil carbon balance). VTT Energian raportteja 9/2000.

Pingoud, K., Perälä, A. and Pussinen, A. 2000. Inventorying and modelling of carbon dynamics in wood products. Proceedings of IEA Bioenergy Task 25 Workshop "Bioenergy for mitigation of CO2 emissions: the power, transportation, and industrial sectors" Gatlinburg, Tennessee 27.–30.9.1999. Graz, Austria: Joanneum Research. Pp. 125–140.

Pingoud, K., Savolainen, I. and Seppälä, H. 1996. Greenhouse impact of the Finnish forest sector including forest products and waste management. Ambio, Vol. 25, No. 5, pp. 318-326.

Ranta, J., Isännäinen, S. and Wihersaari, M. 1996. Recycling of ash in extensive utilisation of biomass. Biomass for energy and the environment. Proceedings of the 9th European Bioenergy Conference. Vol. 1. Comission of the European Communities. Pergamon. Pp. 706–711.

Schlamadinger, B., Apps, M., Bohlin, F., Gustavsson, L., Jungmeier, G., Marland, G., Pingoud, K. and Savolainen, I. 1997.

Towards a standard methodology for greenhouse gas balances of bioenergy systems in comparison with fossil energy systems.

Biomass and Bioenergy, Vol. 13, No. 6, pp. 359-375. Elsevier Science Ltd.

Schlamadinger, B. and Scwaiger, H. 1997. Fuelwood in Europe for Environmental avd Development strategies (FEEDS) – Task 5. GHG emissions along the whole fuelwood technology cycle, for

each technology, per TJ. Joule III report.

Scholz, V., Berg, W. and Kaulfuß, P. 1998. Energy balance of solid biofuels. J. Agric. Eng. Res. 71, pp. 263–272.

Schwaiger, H. and Schlamadinger, B. 1998. The potential of fuelwood to reduce greenhouse gas emissions in Europe. Biomass and Bioenergy, Vol. 15, No. 4/5, pp. 369-377.

Sieppi, S. (ed.) 1999. Finnish Forest Industries Federation. Environmental Report. Statistics for 1998.

Soimakallio, S. and Wihersaari, M. 2002. Puupolttoaineiden tuotannon ja käytön vaikutukset kasvihuonekaasupäästöihin ja niiden rajoittamiseen (The effects of producing

and using wood fuels on greenhouse gas emissions and their abatement). VTT Processes, PRO4/T7509/02.

Statistics Finland 2003. Energy Statistics 2002. Helsinki: Tilastokeskus.

Statistics Finland 2004. Polttoaineluokitus ja päästökertoimet (Fuel classification and emission coefficients). Updated 22.9.2004.

Tekes 2003. Efficient technology for competitive production of forest chips. The Finnish Wood Energy Technology Programme

1999–2003.

Tuhkanen, S. and Pipatti, R. 1999. Uusiutuvien energialähteiden edistämis-ohjelman ympäristövaikutusten arviointi (Environmental

impact assessment of the action plan for renewable energy sources). Ministry of Trade and Industry, 23/1999.

Vesterinen, P. 2003. Regular recycling of wood ash to prevent waste production – RecAsh. A Life Environment Demonstration

Project, Life03 ENV/S/000598. State of the art seminar, VTT Processes, Jyväskylä 1.9. 2003. Seminar report. 19 p.

Wihersaari, M. 1996. Biopolttoaineet ja ympäristö (Biofuels and the environment). Ministry of Trade and Industry, Studies and reports 17/1996.

Wihersaari, M. 2000. Yhdyskuntajätteiden ja metsätähteiden energiakäytön merkityksestä kasvihuonekaasupäästöjen rajoittamisessa

Suomessa (Role of using residues and municipal waste as energy to abate greenhouse gas emissions in Finland). Licentiate thesis. Helsinki University of Technology, Mechanical Engineering.

Wihersaari, M. and Palosuo, T. 2000. Puuenergia ja kasvihuonekaasut. Osa 1: Päätehakkuun haketuotantoketjujen kasvihuonekaasupäästöt (Study of greenhouse gas emissions from final harvest fuel chips production). VTT Energian raportteja 8/2000.

Wihersaari, M. 2003. The role of using bioenergy to abate greenhouse gas emissions in Hungary. VTT Processes, Research report PRO3/7819/03.

|